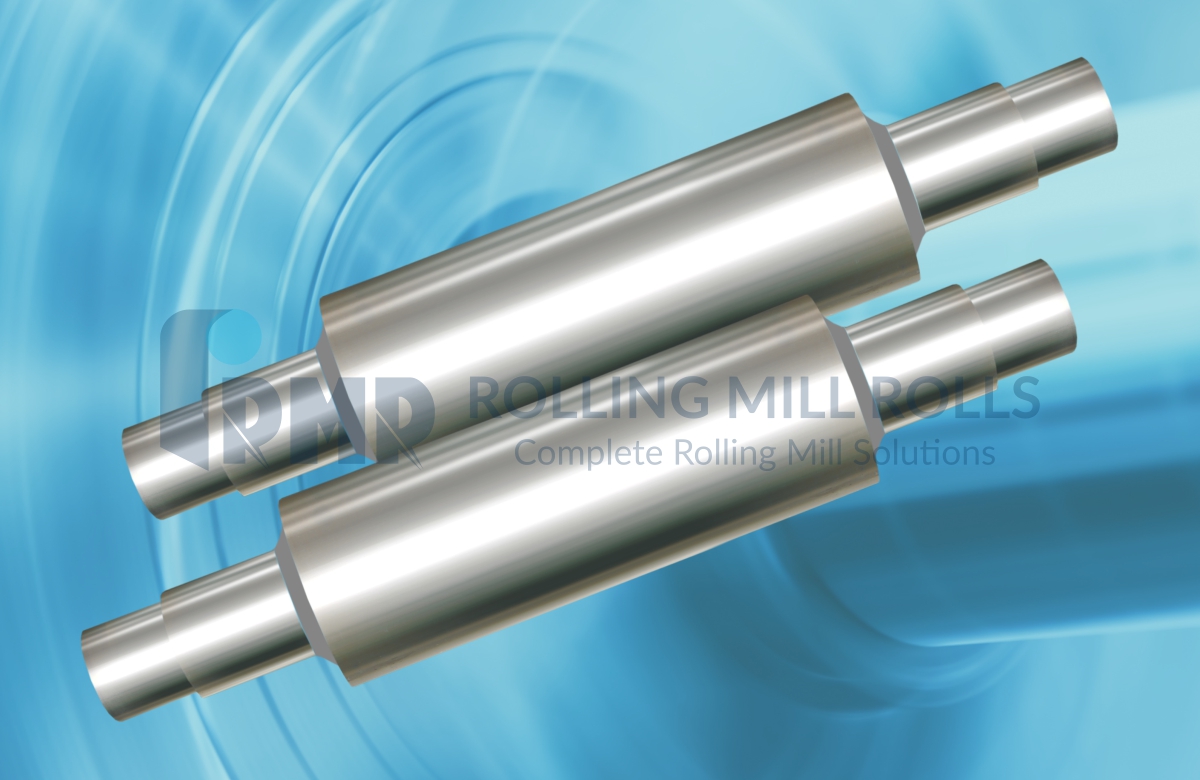

Forged Rolls Manufacturer

Description

Forging is the most commonly used process of shaping the cast metals, by heating and then hammering them, to bring the metal pieces into the desired shapes and sizes, as per the requirements of the customers. The heated metals are then gradually cooled down by reducing the temperature of the furnace, for softening the metals for cutting and shaping up easily. The forged rolls are usually manufactured from carbonated steel or alloyed steel or stainless steel. These rolls are available in many varieties, namely forged M.S. rolls, forged en-8 rolls, forged en-9 rolls, forged en-19 rolls, forged en-24 rolls, forged en-31 rolls, forged en-42 rolls, forged class 2, forged class 3 and many others.

Rolling Mill Rolls manufactures forged rolls with grooves or bearing sizes, for fitting to any other structure. These rolls are offered to other manufacturing companies in totally finished condition or half-finished or black forged conditions, as per the requirement of the clients.

Rolling Mill Rolls is specialized in manufacturing several forged products apart from the forged rolls; like forged rings, forged shafts, forged spindles, forged blanks, forged cranks, forged gear and pinions, forged flanges and forged wheels. All our forged products are certified from the concerned authority and moreover, ultrasonically tested forging materials are offered here, to be put into different types of utilizes in the client companies.

Chemical Composition

| Grade | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

|---|---|---|---|---|---|---|---|---|

En8 |

0.35-0.45 |

0.6-1.00 |

0.05-0.35 |

0.06 |

0.06 |

- |

- |

- |

En9 |

0.5-0.6 |

0.6-1.00 |

0.6-0.35 |

0.06 |

0.06 |

- |

- |

- |

En42 |

0.70-0.85 |

0.5-0.75 |

0.10-0.4 |

0.05 |

0.05 |

- |

- |

- |

En19 |

0.35-0.45 |

0.50-0.80 |

0.1-0.35 |

0.05 |

0.05 |

0.9-1.5 |

- |

0.2-0.4 |

En31 |

0.9-1.2 |

0.3-0.75 |

0.1-0.35 |

0.05 |

0.05 |

1.0-1.6 |

- |

- |

En24 |

0.35-0.45 |

0.45-0.70 |

0.1-0.35 |

0.05 |

0.05 |

0.9-1.4 |

1.3-1.8 |

0.2-0.35 |