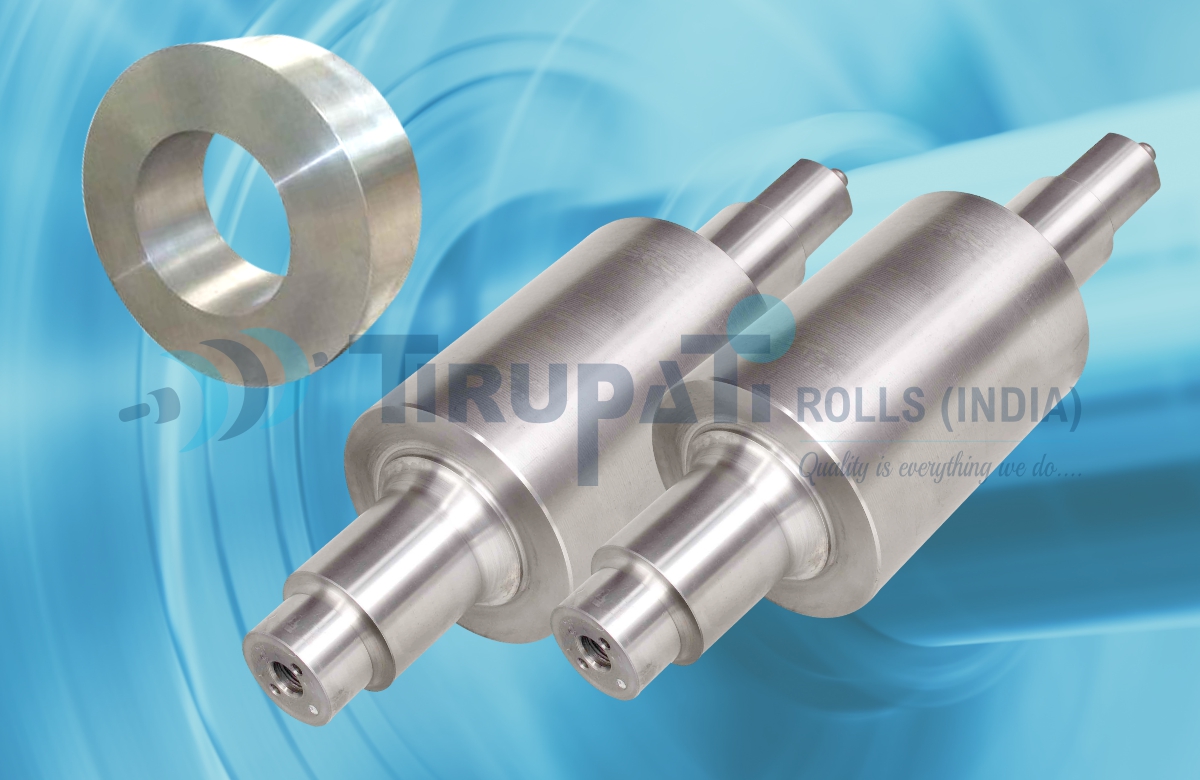

Adamite Rolls & Rings / Alloy Steel Rolls Manufacturer

Description

These Rolls & Rings are alloyed with Nickel, Chromium, Manganese and Molybdenum with Carbon content between 0.50% and 2.00% as well as little amount of Vanadium is also added for the improvement of better microstructure. So, these are capable of a higher mechanical strength with thermal and wear resistance. These Rolls & Rings undergo a sophisticated multi-stage high temperature Heat Treatment (Double Annealing followed by tempering cycle) to give the combination of hardness, toughness and wear resistance required for the particular application. The lower Carbon grades will have a structure consisting of ferrite and fine Pearlite which, as the Carbon content is raised, transitions to a fully Pearlitic Structure and on to one containing free carbide in a matrix of fine Pearlite and even some Bainite for the highest Carbon grades. All rolls of this material are statically tangentially single poured.

Chemical Composition

| Hardness | C% | Mn% | Si% | Cr% | Ni% | Mo% | S% | P% |

|---|---|---|---|---|---|---|---|---|

35-40 |

1.40-1.60 |

0.60-0.90 |

0.40-0.70 |

0.80-1.10 |

0.50-0.70 |

0.15-0.25 |

0.05 MAX |

0.05 MAX |

40-45 |

1.40-1.60 |

0.60-0.90 |

0.40-0.70 |

0.80-1.10 |

0.50-0.70 |

0.15-0.25 |

0.05 MAX |

0.05 MAX |

45-50 |

1.60-1.80 |

0.60-0.90 |

0.40-0.70 |

0.90-1.20 |

0.90-1.10 |

0.20-0.35 |

0.05 MAX |

0.05 MAX |

50-55 |

1.60-1.80 |

0.60-0.90 |

0.40-0.70 |

1.10-1.30 |

1.10-1.30 |

0.25-0.40 |

0.05 MAX |

0.05 MAX |